RFID-based couplings redefine what's possible for controlling, protecting and streamlining fluid handling processes, creating valuable new opportunity for your business.

They allow for the robust transfer of fluid and information in a limitless number of applications across multiple industries. Potential applications include:

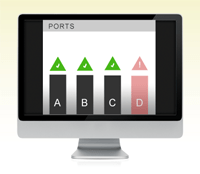

Connection Validation

Challenge: Ensure correct connections in multiple-port systems

Solution: RFID reader reads tag and tells controller what is being connected to each equipment port — controller can display warning to operator or shut down equipment until error is corrected. Each correct line is connected to correct port, preventing harm to equipment, process output or patient.

Operational Control Settings

Challenge: Correctly setting operational controls

Solution: Reader reads tag and tells controller what identification data is on the tag; controller automatically sets operating variables such as pressure, flow rate and operating time duration to match what is required for the device that has been connected to the equipment port. This reduces risk of human error in setting operational controls, preventing harm to equipment, process output or patient.

Usage Control

Challenge: Enforcement of single- or limited-use consumable devices

Solution: Controller tells reader to write to tag each time the limited-use device is connected to the equipment — or write the amount of time the consumable device has been used — and when this threshold has been reached, controller reports to operator that the connected device has reached the end of its life.This reduces risk of damage to equipment, process output or patient due to overuse of consumable device.

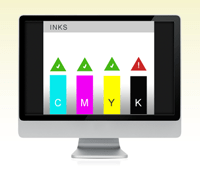

Media Validation

Media Validation

Challenge: Prevent inferior consumable media from damaging equipment

Solution: Reader reads identification data on tag and controller verifies that the approved media/device is being connected to the equipment.This reduces risk of damage to equipment, process output or patient.

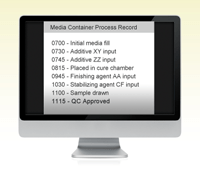

General Purpose Track & Trace

Challenge: Keep an accurate record of process steps

Solution: Media is placed in container with RFID tag, and as the container is connected to various pieces of equipment through each process step (e.g., add ingredients, mix, culture, curing, etc.), the reader on each piece of process equipment writes to the tag a record of what has been completed at that step.This helps eliminate human recording errors and the need for paper copies of process records.

About CPC's intelligent technology

CPC's IdentiQuik® technology is a Radio Frequency Identification (RFID) system for quick disconnect couplings. A patented design embeds RFID-based electronic intelligence into a variety of our most popular and industry-leading coupling configurations, enabling the exchange of rewritable data once the coupling halves come within a few centimeters of one another.

IdentiQuik couplings are ideal for applications with a product involving onboard electronics and parts or media that that are consumable or expensive, along with a need to control the process to ensure the use of the right tool at the right time.

Additional Resources

White Paper: The Role of Intelligent Connectors

Article: Communicate Critical Device and Process Data

Interactive Presentation: Intelligent Fluid Connectors

If you would like to learn more about CPC's intelligent technology OR any of our products, please complete the form, and a CPC representative will be in contact with you.